Process Valves – Our Product Range

PPS offers a wide range of ball valves for many applications across Chemical, Pharmaceutical, Oil & Gas, Food & Beverage, Bio Tech and General Industries. PPS also offer a range of Hygienic ball valves. We are proud distributors for globally established brands such as, Worcester, Tru-flo, Valtek, Atomac, McCanna and Valbart

Size Range ½”–24”, Pressure Classes 150–2500lb

Full and Reduced Bore, 2 Way and Multiport

Floating Ball, Double Block & Bleed and Trunnion mounted design

Industrial and Sanitary design

Fire tested and certified

Design Standards: ISO 17292/API/ASME B16.34/BS5351

Materials Include: Bronze, Carbon, Stainless Steel, Hastelloy, AL6XN and other exotics Lever or gear operated, pneumatic actuators

PPS offer an extensive range of, High Performance, Double Offset and Triple Offset to meet all industry requirements. We are proud distributors of globally established brands such as Atomac, Automax, Durco, Ultraflo

Size Range: 2”– 72”

Wafer, Semi, Fully lugged and Double Flanged design

Resilient and Metal seated, High performance and Triple offset design

Materials include: Cast Iron/Ductile Iron, AluBronze, Carbon, Stainless Steel and exotic materials

Lever and Gear operated

PPS supply a Crane Saunders HC4 diaphragm valves which are engineered for Life Sciences Industry. Saunders IDV provides a diverse range of industrial diaphragm valves in both weir and straight through style

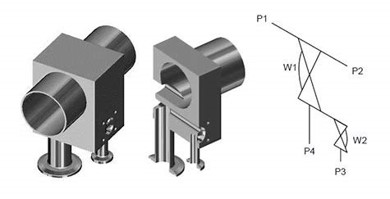

Plug valves are non-lubricated quarter-turn valves that achieve sealing through the use of a compressible sleeve as a sealing member. In many applications, they operate virtually maintenance free for decades.

We provides all of the features and benefits of the conventional sleeved plug valve with the additional benefit of unrivalled ease of maintenance through single module design of all inner components. Not only can this valve be maintained extremely quickly, but it can also be adapted for remote or semi-remote applications. These valves are particularly suited for use in nuclear fuel reprocessing plants, vitrification plants etc.

Sizes 1/2″ thru’ 24″

Available in ANSI 150 thru 600 and DIN PN10/PN100

Flanged, screwed and welded ends

Available in carbon, stainless steel and special alloys

Sleeve materials are PTFE; RPTFE; T-475; T-600; PFA; Xomox 7 and UHMWPE

Multi-port configurations